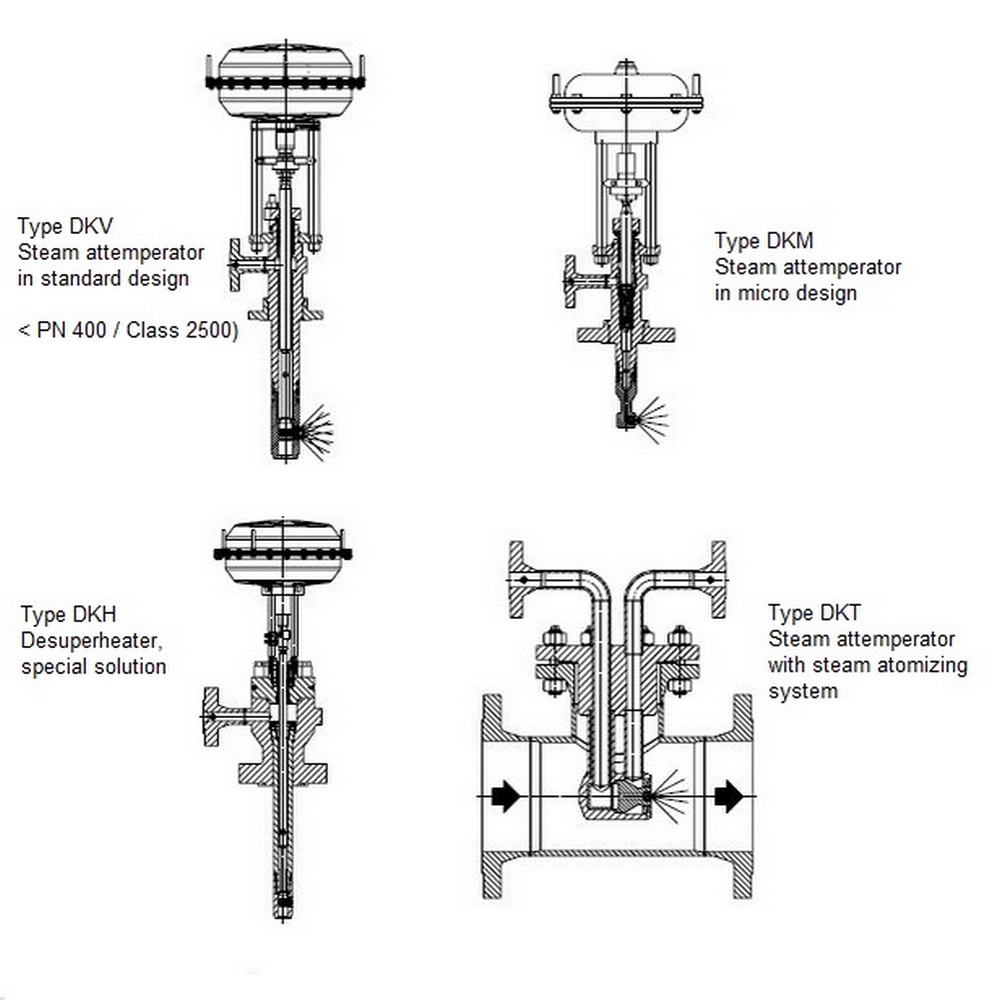

Schroedahl Series DK Type DKV and DKM -Desuperheaters

Last Update

Price:

R.F.Q.

Share Product:

Detail

video on the Desuperheater Valve

Desuperheating (cooling) the steam can simply be achieved by injecting water into the steam flow. When injected, the water is evaporated by means of the desuperheater nozzles. Thereby, the water absorbs heat and consequently the temperature of steam is reduced. The desuperheater type DKV is designed so that even at low injection water quantities an efficient spray of very fine droplets (mist) is obtained.

The nozzles in the sprayhead are designed to give the injection water a high velocity and a radial rotating movement under all conditions. The result is a fine pressure atomization and very quick evaporation.

Features of the DKV desuperheater:

- Optimum characteristics for accurate temperature control available.

- High operating temperature (ASME 650 °C; DIN EN 600 °C)

- Large allowable delta p water/steam pressure difference of up to 100 bar (1450 psi).

- Excellent atomizing characteristics at a delta p water/steam of 5 bar (72.5 psi) and at steam velocity of 10 m/s possible. The field of application starts at steam velocities of 5 m/s and a rate of overheating to the saturation of 3°C. More favorable conditions will improve the effectiveness of the desuperheater.

- Excellent control accuracy for the whole control range.

- Tight shut-off. No leakage in closed position and thus no emptying of the cooling water lines possible.

- No additional control valve required.

- High operation reliability. Due to simple parts, minimal wear.

Specification

| Keyword | |

| Brand | |

| Origin | DE |

Catalogue Download